EBC Brakes, Rotors and Pads

Motorsport Wheels is the regional distributor for EBC Brakes. EBC offers more pad shapes and friction material options than any other competitor so you will be able to find exactly the pad you require for your saloon car, SUV, sports car, luxury or even exotic vehicle.

As a leading EBC brakes dealer, Motorsport Wheels also offers a large range of replacement brake discs and armoured brakes to car owners and fleet operators.

Choose The Right Brakes For You

- EBC Ultimax 2 (OEM Replacement)

- EBC Green Stuff (OEM ++ Pad)

- EBC Red Stuff (Fast Street/Low Brake Dust)

- EBC Yellow Stuff (Fastest Street Pads/Track Day Pads)

- EBC Blue Stuff

Our radically improved Ultimax ECO friendly brake pad is now available for distribution. If you thought our Ultimax brake pad was good, this one is even BETTER!

This is what Ultimax2™ brake pads deliver:

- Superb daily driver R90 type approved pad.

- Features red “brake in’ surface coating for instant safe braking after install.

- New 100 % ECO friendly material with ZERO sulphides.

- No shims for noise reduction needed.

- More bite from cold.

- Works in hot and dry climates as well as in cold.

- Fully R 90 approved as was the original Ultimax grade.

- Ultimax2™ brake pad will supersede on a stock rotation basis its predecessor material and customers will only be supplied Ultimax2™ as stocks of the 2012 sell through or they place a specific order for a production run of 100 sets per reference for a dedicated production batch.

If you simply need a quality OEM replacement pad, look no further than the Ultimax2™ brake pad. Made in the UK Bristol EBC Brakes manufacturing plant, the Ultimax2™ brake pad is a beautifully engineered brake compound that lasts well, produces minimal dust and is the perfect choice for the urban or daily driver. Why spend more if all you need is a quality replacement pad.

The Ultimax2™ brake pad is a total NON-METALLIC pad containing ZERO steel fibre making this a cleaner pad far less aggressive to cast iron brake rotors.

Ultimax2™ has also been graded Code “N” by the USA brake ratings system meaning this receives the TOP award for its environmentally friendly status and has also achieved the much coveted GG friction rating, almost unheard of in the automotive brake Industry.

This equates to a clean pad that lasts longer, extends disc life and emits ZERO toxicity and is a true PAD FOR THE FUTURE. The braking effect with the GG ratting is truly amazing and delivers powerful braking at first brake application. Ultimax2™ has also been widely tested in cold and damp conditions in Northern Europe and Scandinavia and in the Caribbean hot and humid temperatures where brake noise was ZERO.

- GG friction rated highest in brake effect

- Top Rated with Class N by the USA environmental testing to SAE J2975:2011

- EBC medium dust fast street pad with 20-25% brake improvement.

- Built to withstand recurring heavy brake use without brake “fall-off”

- Designed to minimise damage to brake discs or rotors

- Perfectly developed for integration with European sport compacts and lighter Asian models

- ECE Regulation 90 design approved for roadgoing trailers and motor vehicles

- Layered with red “brake in” surface coating for immediate safe braking after installation

Since the launch of its sport range in 1997, EBC Greenstuff brake pads have sold more than 3 million sets of performance automotive brakes globally, making it the bestselling EBC sport pad to date. Today, EBC offer three ranges of Greenstuff brake pads, each one engineered for specialized applications:

- Greenstuff 2000 series – hot hatches and sports compacts

- Greenstuff 6000 series – SUV brake upgrades and small trucks

- Greenstuff 7000 series – SUV Brakes and low dust trucks

- Redstuff ceramic brake pads, passenger car/saloon car pad NOT made for Truck or SUV fitments.

- EBC lowest dust fast street pad with 20-25% % brake improvement.

- Capable of repeated heavy brake use without brake “Fall-Off”.

- Very minimal disc/rotor damage characteristics.

- Superb material for Prestige imports/European and Asian cars.

- ECE R 90 type approved for most cars.

- Features red “brake in’ surface coating for instant safe braking after install.

As EBC’s flagship street brake pad material for prestige and faster cars above 200BHP, the 09 version of EBC Redstuff ceramic Brake pads sets new standards in brake performance. Redstuff ceramic brake pads have always been known for its low dust ability but the latest blend has greatly reduced the phenomenon of pad “Pick up” or disc scoring and reduced dust even further.

As EBC’s flagship street brake pad material for prestige and faster cars above 200BHP, the 09 version of EBC Redstuff ceramic Brake pads sets new standards in brake performance. Redstuff ceramic brake pads have always been known for its low dust ability but the latest blend has greatly reduced the phenomenon of pad “Pick up” or disc scoring and reduced dust even further.

Tested at the UK Motor Industries Research Association (MIRA) in witnessed tests early Redstuff reduced car stopping distance in tests by almost 50 feet from 100 MPH offering a staggering 30% brake improvement.

High friction formula improves brake effect 30-40%.

- Fastest brake pads for Street, Drift & Trackday racing

- Zero brake fade makes this material perfect for fastest driving.

- Capable of repeated heavy brake use without brake “Fall-Off”.

- Very minimal disc/rotor damage characteristics.

- Suitable for shorter track events and race use.

- Medium hardness material feels good at pedal.

- If all you need is stopping power, this is the material choice.

- ECE R 90 type approved for most cars.

- Features red “brake in’ surface coating for instant safe braking after install.

EBC Yellowstuff 1793 compound is a true winner all round, it has high friction from cold, not requiring warm up for street use yet when loaded up and really hot the brakes just get better. Even up to truck weights these pads grip and do not heat fade. They also suitable and the most fastest brake pads for Trackday & Drift racing.

EBC yellows are ECE Brake safety tested which means they must work perfectly from cold at least as good or better than stock pads.

When Yellowstuff see some heat (which is not tested for in the ECE R 90 brake safety regulations) they really show their pedigree. On Japanese cars built with lower friction FF rated pads these deliver a full grade higher stopping and on German cars built with GG these are about the only aftermarket pads that will match or beat the pretty good German OE spec pads and that takes some doing.

EBC Bluestuff is a full competition material developed to utilise the latest carbon-based technology, ensuring both pad and disc wear are minimised.

This material had been developed for most severe races applications and demonstrates exceptional friction stability & wear resistance at extreme temperatures. As such it is particularly well-suited to endurance race application. These armoured brake pads have also been used successfully on heavy armoured vehicle application.

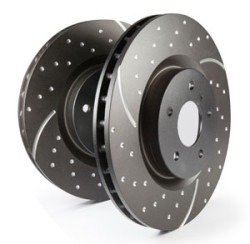

EBC Brake Disc Selection

EBC manufacture the vast majority of its automotive rotors including Premium Brake Rotors in the UK or Europe. Outside these sources where castings or finished rotors have to be bought in to complement the range, the strictest quality controls are applied to ensure the safety and quality of the parts we sell. We source only the highest quality parts from well-known and proven OEM manufacturer vendors and we are responsible for and guarantee those parts to fit and perform as expected. All suppliers of castings for the EBC group are ISO approved to the highest specification and have been visited and approved by the German TUV authorities.

EBC then adds value to its products by strictest quality controls and specifications and a 100% run out and dimensional check, including element analysis, surface finish and hardness tests on every batch and runout inspection. Our rotor machining facility alone is operated and manned by 14 highly skilled staff.

All sport rotors are slotted and grooved at the Las Vegas facility of the USA operation or at our new Northampton rotor facility employing 32 staff which has recently been enhanced to have its own QC department, machining and testing facilities and a new Nitrotherm anti-corrosion coating plant.

Choose from EBC plain non-drilled rotors or sport rotors in two choices – wide aperture GD Sport Rotors series for cooler running or new super silent Ultimax USR slotted rotor series. All EBC rotors including USR Slotted Rotors are British made and are precision machined in the UK. Rotors are made from high-quality grey iron to exacting standards and undergo extensive testing and rigorous quality control. Slotted rotors can significantly improve the performance and longevity of your vehicle’s braking system when used with a matching high friction brake pad set. Having sold hundreds of thousands of brake kits EBC Brakes feel confident their approach is as perfect as it gets.

We are of the opinion that slotted rotors have been “Over sold” by certain marketplace participants and our findings are that a slotted rotor will only give benefits if used with a pad that compensates for its reduced surface area.

New Black GEOMET and NITROTHERMtm FINISH

New Black GEOMET and NITROTHERMtm FINISH

EBC brakes now produce all of its GD series and USR discs with a new, long-lasting corrosion resistant finish. The coating is either the world famous GEOMET or for less popular smaller batch items we use the new NITROTHERM process of anti-corrosive paint applied using this revolutionary process that coats with warm Nitrogen producing a better finish. During 2014, the former GOLD series GD discs was phased out.

EBC recommend the use of a premium pad to complement your new USR slotted rotors which will provide the optimum balance of life and performance.

All EBC sport rotors are final machined in the UK and many of the castings used in EBC rotors are also UK made. During manufacturing, the EBC rotors are 100% runout inspected to a maximum of 0.1 mm total indicator reading or 0.004 inches and should be runout checked after install on your car. If your car develops brake vibration after 3000-4000 miles, this will be due entirely to a run out issue which happens on one in seven road vehicles. Most OEM builders Pro Cut turn rotors from new at install to avoid this problem and EBC recommends highly the Pro Cut on car brake lathes at your disc install.

EBC manufacture 90% of its rotor range in ISO and TÜV approved facilities in the UK or in Italy, all rotors including GD Sport Rotors are machined and finished in the UK and in the USA. Where castings or finished rotors have been bought in to complement the range, the strictest quality controls you can imagine ensuring the safety and quality of the parts we sell. EBC adds value to its products by strictest quality controls and specifications and a 100% run out and dimensional check, plus all USA sport rotors are slotted at the Las Vegas facility of the USA operation. We employ 14 people in our USA rotor machining facility alone and have a bank of 8 HAAS and Feeler CNC machines using the latest CNC controls and tooling for superb accuracy.

Your trusted dealer of high-quality car components

Call us today to know more about our brake discs and pads. Contact us on +97142405553 or email us at info@msw-me.com. You can also drop us a line using our online contact form.